Video Library

Videos Explaining Product Performance

-

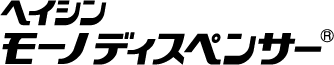

Structure and principle

This video uses CG to explain the structure and principle of the Mohno Pump in an easy-to-understand manner.

-

Features for Applying Fluides

This video uses CG to explain the application features of the Mohno Dispenser.

-

Features for Filling

This video uses CG to explain the filling features of the Mohno Dispenser.

-

Uniform application even at a slant or from the side

It performs high-precision application to both the top and side surfaces. Uniform application to match robot speed is possible, even with multiple shapes.

-

Metered dispensing of high-viscosity fluids

Stable, metered dispensing of high-viscosity fluids, without variation, is possible.

-

Changing flow rate without changing cycle time

The flow rate can be altered without changing the dispensing time.

-

Unrestricted application of both points and lines

It can dispense repeatedly with a high degree of precision, continuously performing point and/or line application.

-

Unrestricted control of line width

The width of the lines can be altered freely, without changing the time.

-

High-precision, repeat point application

It can perform high-precision point application continuously at a high speed, without becoming disordered.

-

Uniform application even of multiple patterns

It can apply uniformly to create a variety of complex shapes without losing the width of the line or the points of lines crossing over each other.

-

Dispensing with 10mm of wide flat nozzle

Instantaneous dispensing of even high-viscosity fluids, it can perform uniform application over a wide area.

-

Dispensing with 50mm of wide flat nozzle

Good fluid control provide consistent application shape.

-

Dot and line dispensing of two-compenent resin

Dispensing while mixing substances like two-component resin.

-

Two-Component Mixture Unit

This unit features two Mohno Dispensers and a static mixer.

Sample Videos for Each Industry

Electrical Machinery

-

Mohno Dispensers for anaerobic adhesive

The HD-R is capable of high-accuracy dispensing of minute amounts of anaerobic adhesive and anaerobic UV resin.

Food

-

Mohno Dispenser for use with food products

High-speed and accurate filling for the food products with no dripping.

-

Metered filling of bottles with oroshi ponzu

It can perform metered filling even of oroshi ponzu (citrus-flavored soy sauce mixed with grated daikon radish) that includes solid components.

-

Filling dressing into bottles

It can perform metered filling even of dressing.

-

Filling ketchup into cups

It can perform metered filling even of ketchup.

-

Filling cookies with jam

This video shows a multi-filling dispenser performing metered filling of jam, without dripping, while interlocking with a conveyor.

Automotive

-

NewApplication of hemming sealer and mastic sealer

Two dispensers in a single robot. Uses Hose-Free System for fast charging of fluids.

-

Stitch application for underpanels with structural adhesives

High-speed application with 50 kg-payload robots. Keeping a constant width with various lengths.

-

Application of stiffener to a door

With its excellent metering performance, high-precision, uniform application over a wide area on a car door is possible.

-

Application of stiffener to a hood

With its excellent metering performance, high-precision, uniform application over a wide area on a car hood is possible.

-

Application of mastic sealer to a door

High-speed, high-precision point application to a car door is possible. The size and shape of the points can also be changed freely.

-

Application of mastic sealer to a hood

High-speed, high-precision point application to a car hood is possible. The size and shape of the points can also be changed freely.

-

Application of hemming sealer to a door

Being able to instantly adjust the application amount makes it possible to match robot deceleration, which allows for uniform line application to doors.

-

Application of hemming sealer to a hood

Being able to instantly adjust the application amount makes it possible to match robot deceleration, which allows for uniform line application to hoods.

-

High-precision application of damping material using a special nozzle

It is capable of wide, high-precision application of damping material using a special nozzle.

-

High-precision, metered application of liquid gasket to a head cover

Metered application to match robot speed is possible, even with complex lines.

Battery

-

Thermal gap filler application on battery mogules

Application of thermal gap filler to a battery.

Cosmetics

-

Filling without destroying bubbles in fluids

It allows for metered filling, without destroying bubbles even in fluids such as hairdressing product (gel).

-

High-accuracy filling of high-viscosity fluids with good fluid control

High-accuracy filling is possible, with good fluid control of even high-viscosity fluids like Vaseline and hand cream.

Chemical, etc.

-

High-accuracy filling of syringes with metal paste

High-accuracy, metered filling allows for improved yield, cutting down on waste of materials.

-

Metered filling of chemicals into containers

Models with an integrated hopper make it possible to reduce residual fluid amounts, preventing expensive raw material from going to waste.

Introduction to our company

-

Heishin Company Introduction Video

This is a video introducing Heishin Ltd.

-

Product Square Introduction

This is a video introducing Product Square that i-s Heishin's product showroom, located in the Shiga Business Complex.