Structure and Principle

High-accuracy, Metered Dispensing

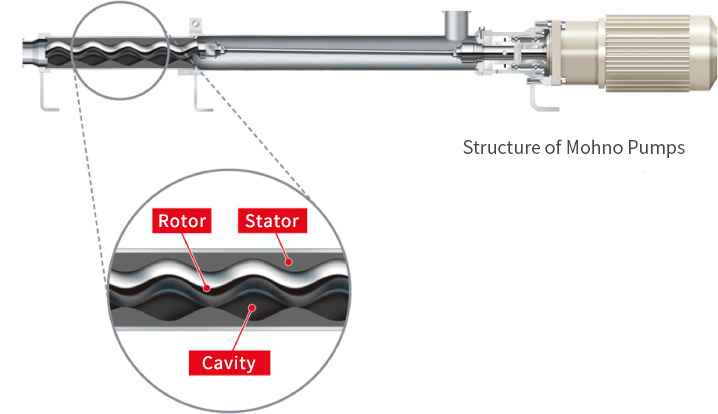

Structure of Mohno Dispensers

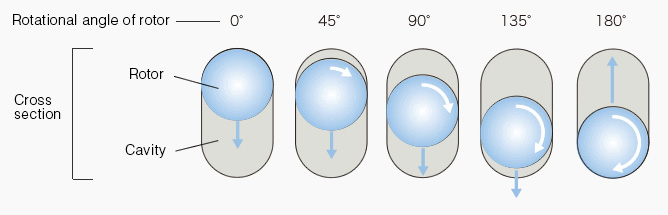

The standard structure of Mohno Dispensers is the same as Mohno Pumps and features a progressing cavity pump that uses rotary positive-displacement. The central part is composed of a rotor equivalent to male threads and a stator equivalent to female threads. In the gap between the rotor and the stator, a series of independent sealed chambers called "cavities" is created.

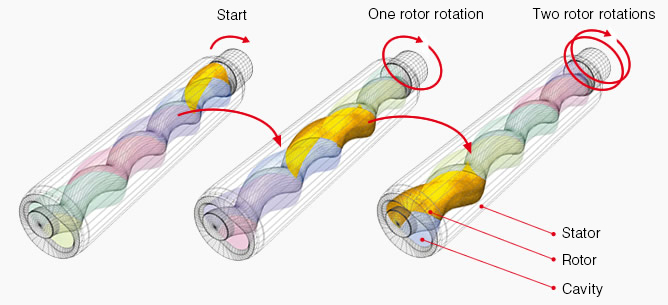

Principle of Mohno Dispensers

When the rotor turns in the stator, a suction force that draws in high-viscosity fluids is produced, and as each new cavity is created, the cavities move toward the dispense end. Fluid drawn into the cavity is conveyed in a sealed chamber and continuously conveyed forward.

The cross-sectional area of each cavity is always constant regardless of the position of the rotor, enabling a constant flow rate that is directly proportional to the rotational speed of the rotor.

Features and Advantages

Mohno Dispensers can, by working on the principles of progressing cavity pumps, perform high-accuracy dispensing.