Determination

A Manufacturer on the Cutting Edge of Progressing Cavity Pumps

Heishin was founded in Kobe, Hyogo Prefecture in 1968, as a specialist manufacturer of progressing cavity pumps. The progressing cavity pump was invented in the 1930s by the French aviator René Moineau, and is a type of pump that conveys fluid by turning a screw. At the time of our founding, the progressing cavity pump was not very well established in Japan, so we learned from manufacturers in Europe, specifically Germany, when we established our business.

In 1969 we were finally able to sell our self-produced progressing cavity pump, the very first model of the Mohno Pump to a ship manufacturer. Since then, Mohno Pumps' sterling reputation for providing non-pulsating, metered conveyance of various fluids has grown ever stronger, and we have continued to vigorously pursue manufacture, research and development. One of our company policies is: "Create original products to achieve business independence." Just as that policy says, we do not simply copy the models of other companies and sell a variety of pumps, but rather pursue that which can only be done by the Mohno Pump. In order to meet the various demands of our customers, we have cultivated technological strength for problem-solving and a creative force to pump out high-quality products.

In more than five decades of running our business, we have developed a wide variety of Mohno Pumps to suit various applications, and they are today used in everything from water and sewage transport to food, chemicals, electrical machinery and the automotive industry.

The Dawning of the High-precision Dispenser, Utilizing Our Know-How

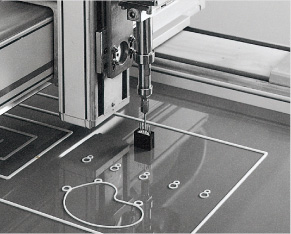

The Mohno Dispenser, our first dispenser product, was developed as an applied product of the Mohno Pump. It came into being in 1986, almost 20 years after our company's founding. We created it because our customers were demanding a device that could perform uniform application of adhesives.

The Mohno Dispenser maintains the classic Mohno Pump's famous non-pulsating, metered handling of a wide variety of fluids, and can perform application and filling with a high degree of precision on fluids, from high-viscosity adhesives to highly abrasive metal pastes to grated daikon radish which is easy to settle.

Building on the knowledge and experience we accumulated from the R&D and manufacture of Mohno Pumps we developed models, peripheral equipment and system products to meet customers' requests, as well as dispenser-specific applications. In this way we have now built up a 30+ year history of tremendous achievements in as a dispenser manufacturer.

Determination for Creation

Heishin's product creation is designed to accommodate our customers' needs in as much detail as possible. We receive a lot of inquiries along the lines of "Any other way we tried it it didn't work out" or "Isn't there any way you can make this work?" So by full utilization of our decades of experience, performing rigorous tests on actual pump and dispenser work, perform research on new and untried materials, and so on, putting all of our energy into helping solve any problems our customers may have.

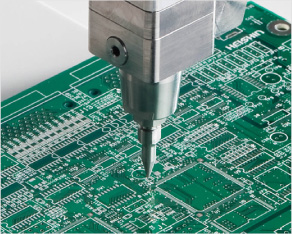

Manufacture

We make all of our products, such as Mohno Pumps and Mohno Dispensers, at our Shiga Business Complex in Nagahama, Shiga Prefecture. The core components—the rotors and stators—are each manufactured in their own factories. The assembly plant, where we handle the processes from assembly to shipping, does not run on line production but rather on a cell production system, wherein a single worker monitors the production of a single device until its completion. This allows us to be flexible and meet the needs of customers who request customized products. After each product is completed, it is assessed according to the rigorous, multi-criterion Heishin quality standards, and only once it has passed this assessment is it shipped out.

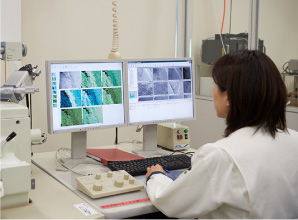

Research and Development

Component development, materials research and so on for rotors and stators are performed at the Technical Institute, a technical research base where we perform development on products and systems to meet all of our customers' needs. We also perform groundbreaking research here to address the demand for ever better fluid conveyance that does not even exist yet.