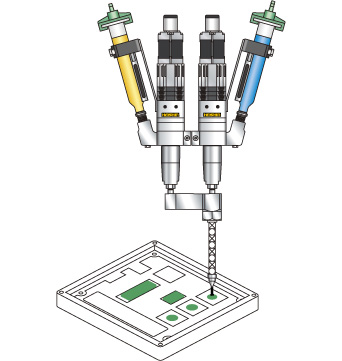

ProductsTwo-Component Mixture Unit

Product Features

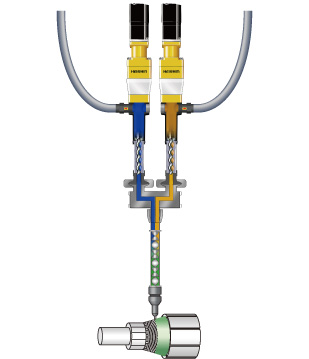

Performs high-accuracy dispensing while mixing two-component adhesives. This unit features two Mohno Dispensers and a static mixer.

●Mixing ratio and flow rate are easy to adjust

By controlling the rotation of the rotor, it is easy to control the mixing ratio and the flow rate.

●Stable dispensing of high-viscosity fluids

Mohno Dispensers support fluids with a wide range of viscosity, exceeding 500000 mPa•s.

●High mixing precision

Stable mixing precision can be maintained even when there is considerable difference in viscosity or volume between the two components.

●Reducing material loss

By eliminating batch processing such as mixing by hand, and dispensing the exact amount needed, Mohno Dispensers can save material.

- Primary Applications

- Application of two-component curing thermal silicone grease to an engine control unit

- Application of an insulative two-component silicone resin to a motor

- Sealing the back sonar circuit board of an automobile

- Adhesion to a cell sheet

- Filling the joints in tiles

- Fluids

- Two-component epoxy resin

- Two-component silicone resin