ApplicationsStable mixing and high-precision application of two component hardening epoxy adhesives

- Industry

- Electrical machinery

- Fluid

- Two component hardening epoxy adhesives

Current challenges and requests

In the manufacturing process of electronic components, two-component hardening epoxy adhesive is mixed and applied in a trace amount.

- However, due to its high viscosity, application takes several dozen seconds.

- If the viscosity of adhesive changes due to the surrounding temperature change, the adhesive does not mix properly, causing unstable application volume. The discharge volume needs to be adjusted accordingly.

To improve productivity and quality, the customer wants to bring in equipment that helps to cut application time and provides trace amounts of stable application.

Solutions and merit when improved

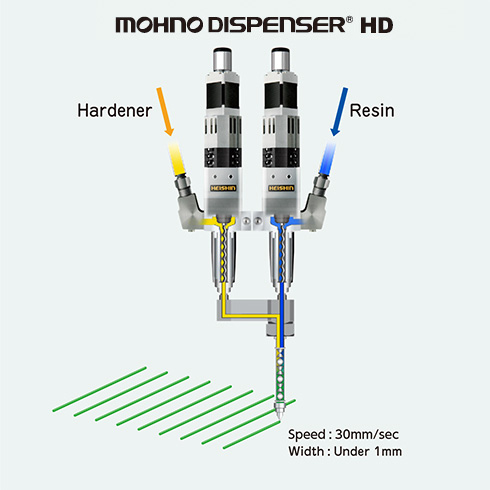

Two Mohno Dispensers 3HD025G30 and a single static mixer were introduced.

- The newly introduced equipment can handle highly viscous fluid with high precision and provide a trace amount application, helping to reduce the application time more than half.

- Insusceptible to change in viscosity, consistent application was provided even the surrounding temperature varies.

- Instantaneous reverse rotation at the completion of discharge prevents drips and eliminates the need for wasteful tasks such as wiping off excess fluid.

Related information

-

Electrical Machinery

- Constant application of insulators in the motor production process

- Wide application of sealant to solar cell cover glass

- Line application of trace amounts of adhesives on resin case of electronic component

- Minute line application of high-viscosity adhesives on smartphone body

- High-precision dot application of solder paste without being affected by residual fluid fluctuation in a barrel (syringe)

- Stable mixing and high-precision application of two component hardening epoxy adhesives

- Food

-

Automotive

- Highly viscous thermally conductive material is applied to electric components

- Application of anti-seizure lubricant is automated

- High-precision dot application of high-viscosity heat-dissipating silicone on downsized electrical components for automotive

- Wide application of heat-dissipating silicone using flat nozzle

- Cosmetics

- Chemical, etc.