ApplicationsWide application of sealant to solar cell cover glass

- Industry

- Electrical

- Fluid

- Silicone resins (frame sealers and glass sealers)

Current challenges and requests

In the manufacturing of solar cells, there is a process in which sealants are widely applied between cover glass that are on the surface of modules and aluminum frames. With conventional equipment, dripping made the product and the surrounding areas unclean after the application process, and required a post-cleaning process.

There were also other issues such as a need for a post-application adjustment as the conventional equipment did not discharge fluids at a constant rate, and high viscosity fluids slowed the application speed, which decelerated production speed.

Solutions and merit when improved

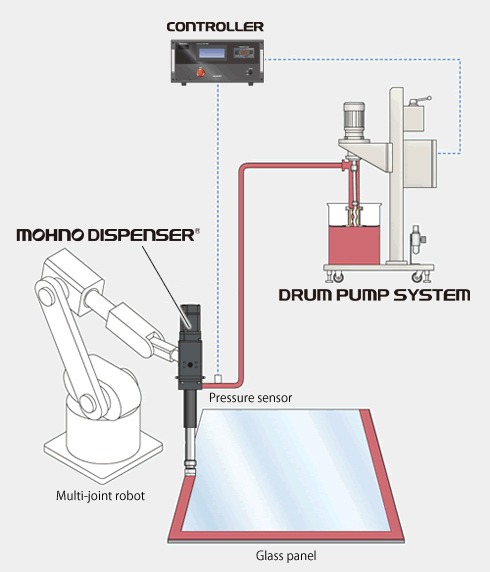

Mohno Dispenser is installed due to its no dripping and high precision constant discharge capabilities.

- Reverse motion after application prevented dripping, and the post-cleaning process became unnecessary, as products and the surrounding areas were kept clean.

- With its excellent constant rate discharging, the application forms were stable, and a need for post-application correction processes is eliminated.

- Stable discharge even for high viscosity liquid shorten the cycle time.

- By controlling rotational speed to adjust to minimum necessary application volume, losses of silicone resins were prevented.

Related information

-

Electrical Machinery

- Constant application of insulators in the motor production process

- Wide application of sealant to solar cell cover glass

- Line application of trace amounts of adhesives on resin case of electronic component

- Minute line application of high-viscosity adhesives on smartphone body

- High-precision dot application of solder paste without being affected by residual fluid fluctuation in a barrel (syringe)

- Stable mixing and high-precision application of two component hardening epoxy adhesives

- Food

-

Automotive

- Highly viscous thermally conductive material is applied to electric components

- Application of anti-seizure lubricant is automated

- High-precision dot application of high-viscosity heat-dissipating silicone on downsized electrical components for automotive

- Wide application of heat-dissipating silicone using flat nozzle

- Cosmetics

- Chemical, etc.