ApplicationsHighly viscous thermally conductive material is applied to electric components

- Industry

- Automobiles and electrical

- Fluid

- Heat spreading materials(thermal grease and heat spreading grease)

Current challenges and requests

High viscosity heat spreading materials are applied on electrical components. However, with conventional devices, unstable application volume, long discharge time, and the production efficiency needed improvement.

When wishing to change materials to highly conductive heat spreading materials, the assumedly higher viscosity of such materials made it impossible to handle.

Solutions and merit when improved

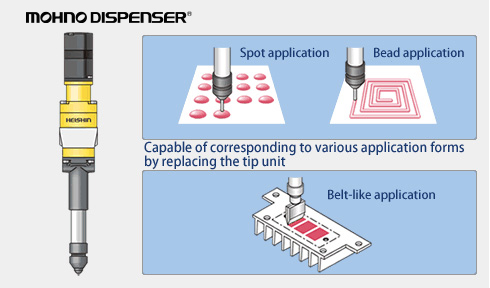

Mohno Dispenser is installed for its stable discharge capability, even of highly viscous liquid.

- The application volume is stabilized and quality is enhanced.

- The cycle time during the application process is shortened to result in an improvement in productivity.

- Stable application was achieved for belt-like application, and various forms of application became possible.

Related information

-

Electrical Machinery

- Constant application of insulators in the motor production process

- Wide application of sealant to solar cell cover glass

- Line application of trace amounts of adhesives on resin case of electronic component

- Minute line application of high-viscosity adhesives on smartphone body

- High-precision dot application of solder paste without being affected by residual fluid fluctuation in a barrel (syringe)

- Stable mixing and high-precision application of two component hardening epoxy adhesives

- Food

-

Automotive

- Highly viscous thermally conductive material is applied to electric components

- Application of anti-seizure lubricant is automated

- High-precision dot application of high-viscosity heat-dissipating silicone on downsized electrical components for automotive

- Wide application of heat-dissipating silicone using flat nozzle

- Cosmetics

- Chemical, etc.